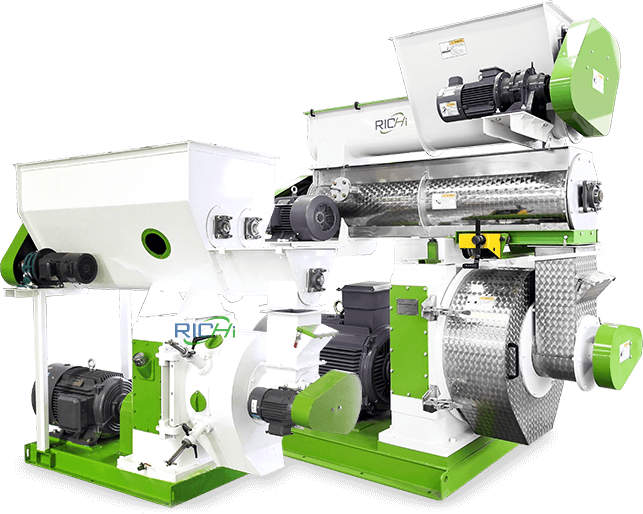

Recently, biomass pellet investment jobs have actually slowly obtained appeal, as well as wood pellet makers are important equipment for the production of bio pellet fuels.

Some customers are puzzled when they buy wood pellet equipments due to the fact that they are new to this sector: the wood pellet maker equipment market is mixed, and there are large and small producers. Should you choose large-scale pelletizing equipment or small-scale equipment?

Numerous clients have such considerations: first get small outcome, economical investment, as well as utilize it, begin small investment initially, and boost financial investment after generating income.

As a matter of fact, it is regular to have such a suggestion, however the adhering to points require to be taken note of when picking equipment:

1. Preliminary preparation

Make good financial investment spending plans, check raw materials, factories, electricity, as well as sales markets.

2. Identify the equipment according to the material

Different materials have different production procedures and various equipment called for. Power usage and result, upkeep expenses, whether it can be quickly repaired, whether putting on components are wear-resistant, and whether the procedure is convenient demand to be thought about. Find a couple of more makers to clarify the scenario, and we will make a plan for you for free.

3. Select reliable suppliers

On-site evaluation, when necessary, you can bring the materials to check the equipment. Regular producers normally have after-sales educating to find out how to make use of the equipment

Realities have confirmed that an excellent driver not only has high granulation efficiency, but likewise understands how to maintain equipment as well as can prolong the service life of the machine.

4. Choose large granulating equipment.

Under the exact same manufacturing jobs, the large pellet equipment saves labor and also is convenient for administration. For instance, the range of 8 equipment can conserve 1 million labor each year. As well as the large pellet equipment conserves floor space, about half of the room.

Furthermore, it saves the number of repair work and also components, the moment for parts purchase and also substitute, as well as the labor needed for replacement.

Large pellet mills are a lot more advanced in design, far better in security, motor power and torque, and have a variety of relevance.

The production is less complicated to release, and it is easier to attain scale results and also lower production prices. The overall stability of the maker is good, and the investment price is naturally high.