Introduction to Goat Feed Making Machine

In the realm of modern livestock farming, the quality and efficiency of feed production play a pivotal role in the health and productivity of animals. For goat farmers, ensuring a consistent supply of high-quality feed is essential to maintaining the well-being of their herds. This is where a goat feed making machine becomes indispensable. These machines are designed to process raw materials into nutritious feed pellets that are easy to store, transport, and feed to goats. In this article, we will explore the features, applications, and benefits of goat feed making machines, with a particular focus on RICHI Machinery’s offerings. Additionally, we will discuss the structure and working principle of these machines, their industry prospects, and the auxiliary equipment necessary for a complete feed production line.

Application of Goat Feed Making Machine

Goat feed making machines are versatile tools that can be used in various farming scenarios. Whether you are a small-scale farmer looking to produce feed for a few goats or a large-scale operation needing to supply feed for hundreds of animals, these machines offer numerous benefits.

- Small-Scale Farming: For small-scale farmers, a goat feed making machine provides an economical solution to producing high-quality feed on-site. This not only reduces the cost of purchasing commercial feed but also allows farmers to control the quality and composition of the feed, ensuring it meets the specific nutritional needs of their goats.

- Large-Scale Operations: In larger farming operations, goat feed making machines are essential for maintaining a steady supply of feed. These machines can produce large quantities of feed pellets quickly and efficiently, which is crucial for operations with a significant number of animals. The ability to produce feed on-site also reduces the dependency on external suppliers and the associated costs.

- Improved Feed Consistency: One of the key advantages of using a goat feed making machine is the consistency it brings to feed production. By pelletizing the feed, farmers can ensure that each pellet contains a uniform mix of nutrients, which is important for the health and growth of the goats.

- Reduced Feed Wastage: Feed pellets are less prone to wastage compared to loose feed. Goats are less likely to sort through the pellets, ensuring they consume the entire ration and receive all the necessary nutrients.

The Advantages of Sheep Feed Pellets

Pelletized feed offers several advantages over traditional loose feed, particularly in the context of goat and sheep farming. The following are some of the key benefits of using sheep feed pellets:

- Nutritional Consistency: Each pellet is formulated to provide a balanced mix of nutrients, ensuring that the goats and sheep receive the necessary proteins, vitamins, and minerals in every bite. This consistency is crucial for promoting healthy growth and maintaining overall animal health.

- Enhanced Digestibility: The process of pelletizing feed involves the application of heat and pressure, which helps break down certain components of the feed. This makes the feed easier for goats and sheep to digest, leading to better nutrient absorption and improved feed conversion ratios.

- Better Growth Rates: Animals that are fed a balanced diet in pellet form typically exhibit better growth rates compared to those fed loose feed. This is because the uniform nutrient distribution in the pellets ensures that the animals receive the right amount of energy and nutrients needed for optimal growth.

- Improved Feed Handling: Feed pellets are easier to handle, store, and transport than loose feed. They take up less space, have a longer shelf life, and are less likely to spoil or be contaminated during storage.

- Reduced Feed Wastage: Pellets minimize feed wastage as goats and sheep are less likely to sort through the feed, picking out their favorite parts and leaving the rest. This ensures that the animals consume the entire ration, maximizing the feed’s nutritional value.

The Structure and Working Principle of RICHI Goat Feed Making Machine

RICHI goat feed making machines are engineered with precision and designed to provide high-efficiency feed production. Understanding the structure and working principle of these machines is essential for maximizing their potential.

- Key Components:

- Die and Rollers: The die is a metal plate with holes through which the feed mixture is forced by the rotating rollers. The size and shape of the pellets are determined by the die.

- Feeder: The feeder controls the flow of raw materials into the machine. It ensures that the materials are fed evenly into the conditioning chamber, preventing blockages and ensuring consistent pellet quality.

- Conditioner: The conditioner adds steam to the raw materials before they enter the pelletizing chamber. This softens the materials and makes them easier to compress into pellets. It also improves the digestibility of the feed.

- Pelletizing Chamber: This is where the actual pellet formation occurs. The raw materials are compressed through the die by the rollers, forming pellets.

- Cooling System: After the pellets are formed, they are still hot and soft. The cooling system hardens the pellets and reduces their moisture content, making them suitable for storage and transport.

- Working Principle:

- Material Intake: The raw materials are fed into the feeder, which regulates the flow into the conditioner.

- Conditioning: In the conditioner, the materials are mixed with steam, which increases their temperature and moisture content, making them pliable for pelletizing.

- Pelletizing: The conditioned material is then forced through the die by the rollers. The pressure and heat generated during this process form the raw materials into dense, uniform pellets.

- Cooling: The freshly formed pellets are transferred to the cooling system, where they are cooled to ambient temperature. This step is crucial for maintaining pellet integrity and preventing mold growth during storage.

- Sifting and Packaging: The cooled pellets are sifted to remove any fines or broken pellets, then packaged for distribution or storage.

RICHI Goat Feed Making Machine Types

RICHI offers a range of goat feed making machines to meet the needs of different farming operations. These machines vary in size, capacity, and features, allowing farmers to choose the one that best suits their specific requirements.

- Small-Scale Models: Designed for small farms or hobbyists, these machines offer a lower production capacity but are highly efficient and easy to operate. They are ideal for farmers who need to produce feed for a smaller number of goats.

- Medium-Scale Models: These machines are suitable for medium-sized farms and can produce a larger quantity of feed pellets. They offer a good balance between capacity and cost, making them a popular choice for many farmers.

- Large-Scale Models: For commercial operations that require high-volume feed production, RICHI offers large-scale pellet mills. These machines are capable of producing thousands of kilograms of feed per hour and are designed for continuous operation.

- Customized Models: RICHI also offers customized feed making machines tailored to the specific needs of individual customers. These machines can be designed with specific features or capacities to meet unique production requirements.

What Other Pellets Can RICHI Sheep Feed Pellet Machine Produce?

RICHI’s sheep feed pellet machines are not limited to producing only goat and sheep feed pellets. With minor adjustments, these machines can be used to produce a variety of other feed types, making them a versatile investment for farmers who raise multiple species of livestock.

- Cattle Feed Pellets: The same machine can be used to produce pellets for cattle, provided the appropriate die and formulation adjustments are made.

- Poultry Feed Pellets: With a change in the die and feed composition, the machine can produce high-quality poultry feed pellets.

- Rabbit Feed Pellets: Similar to goat feed, rabbit feed can also be produced using the same pellet mill with minimal modifications.

- Fish Feed Pellets: While more specialized, RICHI machines can be adapted to produce floating or sinking fish feed pellets, depending on the needs of the farmer.

Sheep Feed Pellet Machine Industry Prospects

The global feed pellet machine industry is experiencing significant growth, driven by the increasing demand for high-quality, pelletized feed in the livestock sector. Several factors contribute to the positive outlook for the sheep feed pellet machine industry:

- Rising Livestock Populations: As the global population grows, so does the demand for meat and dairy products. This has led to an increase in livestock farming, which in turn drives demand for efficient feed production solutions.

- Growing Awareness of Animal Nutrition: Farmers are increasingly aware of the importance of providing balanced and nutritious feed to their animals. This has led to a greater demand for pelletized feed, which offers consistent nutrient content.

- Technological Advancements: Advances in feed pellet machine technology have made these machines more efficient, reliable, and affordable. This has expanded their accessibility to a broader range of farmers, from small-scale operations to large commercial enterprises.

- Environmental Considerations: Pelletized feed is more environmentally friendly than loose feed, as it reduces wastage and minimizes the risk of spoilage. This is becoming increasingly important as farmers seek to adopt more sustainable practices.

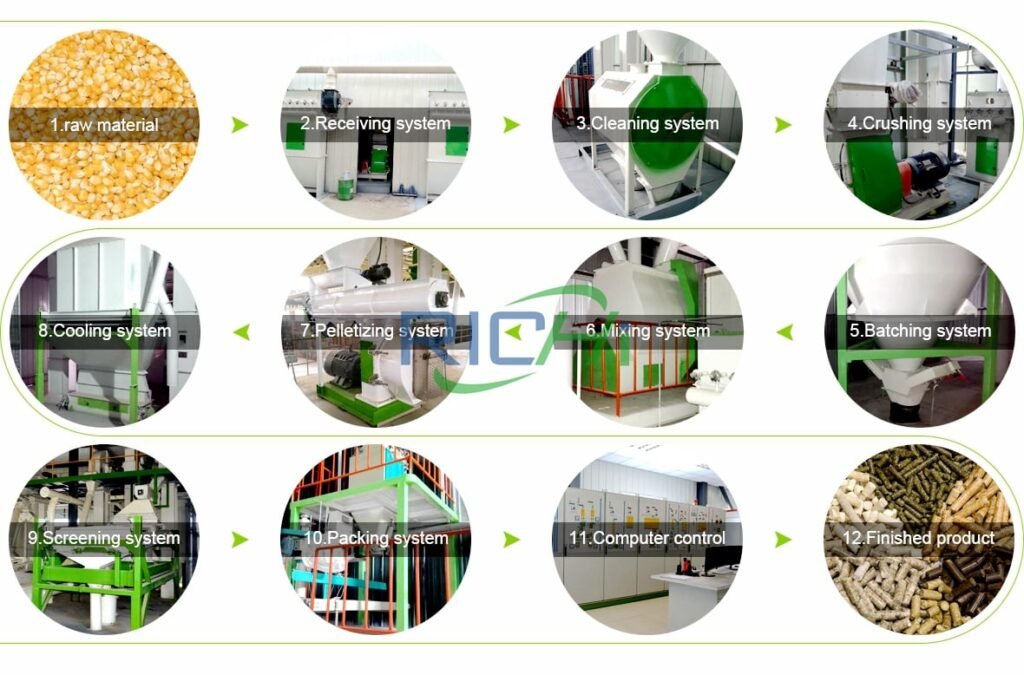

What Are the Auxiliary Equipment of Goat Feed Plant?

A complete goat feed production line requires several auxiliary machines in addition to the feed pellet mill. These machines work together to ensure efficient production and high-quality feed pellets.

- Feed Grinder: The feed grinder is used to pulverize raw materials into a fine powder before they are mixed and pelletized. This step is crucial for ensuring uniform pellet quality.

- Feed Mixer: The mixer blends the ground raw materials into a homogenous mixture. This ensures that each pellet contains the correct balance of nutrients.

- Conveyor Systems: Conveyors transport the raw materials and finished pellets between different stages of the production process. They improve efficiency and reduce manual labor.

- Cooler: After the pellets are formed, they need to be cooled to harden and reduce moisture content. The cooler is an essential piece of equipment for ensuring the durability and shelf life of the pellets.

- Sifter: The sifter separates fines and broken pellets from the finished product. This ensures that only high-quality pellets are packaged and sold.

- Packaging Machine: The packaging machine is used to bag the finished pellets for storage or sale. It ensures that the pellets are protected from contamination and moisture during storage.

Installation and Operation of Sheep Feed Pellet Machine

Proper installation and operation of a sheep feed pellet machine are crucial for maximizing its efficiency and lifespan. The following steps outline the process:

- Site Preparation: Before installation, ensure that the site is properly prepared. This includes having a solid, level foundation for the machine and adequate space for operation and maintenance.

- Machine Installation: The machine should be installed according to the manufacturer’s instructions. This typically involves securing the machine to the foundation, connecting it to power, and installing any necessary auxiliary equipment.

- Initial Testing: Before starting full-scale production, the machine should be tested to ensure it is functioning correctly. This includes checking the feeder, conditioner, and pelletizing chamber for proper operation.

- Operator Training: Operators should be trained on how to use the machine safely and efficiently. This includes understanding the control panel, feeding system, and emergency shutdown procedures.

- Regular Maintenance: To keep the machine running smoothly, regular maintenance is essential. This includes checking for wear and tear, lubricating moving parts, and replacing any damaged components.

RICHI Sheep Feed Pellet Machine After-Sales Services

RICHI Machinery is committed to providing comprehensive after-sales support to its customers. This includes:

- Technical Assistance: RICHI offers technical support to help customers troubleshoot and resolve any issues with their machines. This can be done remotely or through on-site visits by trained technicians.

- Spare Parts Supply: RICHI maintains a stock of spare parts for all its machines, ensuring that customers can quickly replace any worn or damaged components.

- Maintenance Services: Regular maintenance is essential for keeping the machine in good working condition. RICHI offers maintenance services to help customers keep their machines running smoothly.

- Operator Training: RICHI provides training programs for operators, helping them to maximize the efficiency and lifespan of the machines.

- Global Service Network: With a global service network, RICHI can provide timely support to customers around the world, ensuring that their feed production operations continue without interruption.

Conclusion

Investing in a goat feed making machine is a smart decision for any farmer looking to improve feed quality and production efficiency. RICHI Machinery offers a wide range of feed pellet machines designed to meet the needs of different farming operations. Whether you are a small-scale farmer or a large commercial operation, RICHI has the expertise and equipment to help you succeed. By understanding the benefits of sheep feed pellets, the structure and working principle of the machine, and the importance of auxiliary equipment, you can make informed decisions that will enhance your feed production capabilities and contribute to the success of your business.